The XCT8500 universal industrial X-ray inspection system consists of a X-ray source, detector, scanning system, image reconstruction and analysis system. It can achieve inspection methods such as 2D/3D/CT, and is suitable for quality inspection, 3D measurement, and non-destructive analysis.

Characterizing the micro-scale features of the internal structure of the sample, combined with qualitative and quantitative analysis software to achieve multi-angle measurement and analysis of the sample, as well as automatic determination of OK/NG conditions, and to provide effective data for product quality inspection.

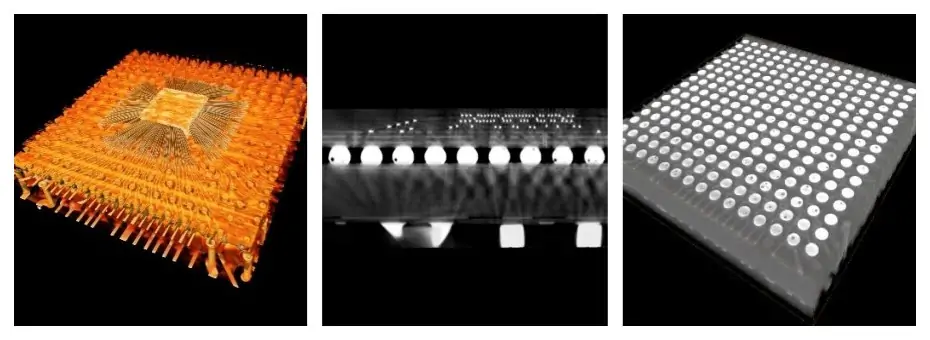

It can be used for electronic component soldering quality inspection, BGA component, integrated circuit (IC) and its binding line inspection, semiconductor packaging inspection and internal connection, electronic power (IGBT) module inspection, and Wafer defect inspection (WLCSP).Including missing parts, deviation, tin connection,contamination, faulty soldering, component foot warping, voids, pillow effect, and other soldering abnormalities.

Advantages of XCT8500 Universal Industrial X-ray Inspection System

- With Planar CT Function (PCT), It Can Be Applied To 3D/CT Inspection Of Printed Circuit Boards, SMT, IGBT, Wafers, Etc.

- With cone beam CT function, it can be applied to the inspection of sensors, relays, micro motors, materials, and aluminum castings.

- Convenient 360° fixed-point observation mode.

- 2D void inspection software module (optional)

- 3D measurement and analysis software module (optional)

Application Cases

XCT8500 adopts open micro-focus transmission X-ray source, the inspection ability can reach 0.5μm. It can realize 2D/3D/CT and other inspection methods, and is suitable for quality inspection,three-dimensional measurement and non- destructive analysis.

Specification Of XCT8500 Universal Industrial X-Ray Inspection System

(1) X-RAY Tube Parameters

| Tube Type | Open micro-focus transmission X-ray source |

|---|---|

| Tube Voltage Range | 20 ~160KV |

| Tube Current Range | 0.01mA ~ 1.0mA |

| Maximum Tube Power | 64W |

| Maximum Target Power | 15W |

| Minimum Object Distance (FOD) | < 300 μm |

| Micro Focus Size | < 1 μm |

| Minimum Defect inspection Capability | <500 nm |

(2) Flat Panel Detector Parameters

| Flat Panel Type | Amorphous silicon flat panel detector (optional) |

|---|---|

| Pixel Matrix | 1536×1536 |

| Field of View | 154mm×154mm |

| Resolution | 5.0Lp/mm |

| Image Frame Rate(1×1) | 30fps |

| AD Conversion Digits | 16bits |

(3) 3D/CT Parameters (Optional Function)

| CT Scan Cycle | 20s |

|---|---|

| CT Reconstruction Time | 30s |

(4) Equipment Performance Parameters

| Maximum Sample Size | 645mm×635mm |

|---|---|

| Maximum inspection Area | 500mm×500mm |

| Image Geometric Magnification | 2500X |

| Input Power Supply | 220V 10A 50 – 60HZ |

| Control System | DELL OptiPlex 7000MT v12.0 i9 graphics workstation |

| Dimensions | L1500mm×W1650mm×H2250mm |

| Net Weight | About 2950KG |